More Smoke, Less Mirrors

A back to basics overview of smoke testing

Used extensively for over 60 years, smoke testing has proven to be a vital ingredient of successful inflow and infiltration (I&I) studies. Its popularity has continued as more contractors and municipalities are performing smoke tests every year. With the continued popularity of smoke testing comes increased competition among manufacturers of smoke testing equipment. With increased manufacturers, products and creative advertising, it can get confusing when it comes time to specify equipment and do the test. This article will help clear up some of that confusion.

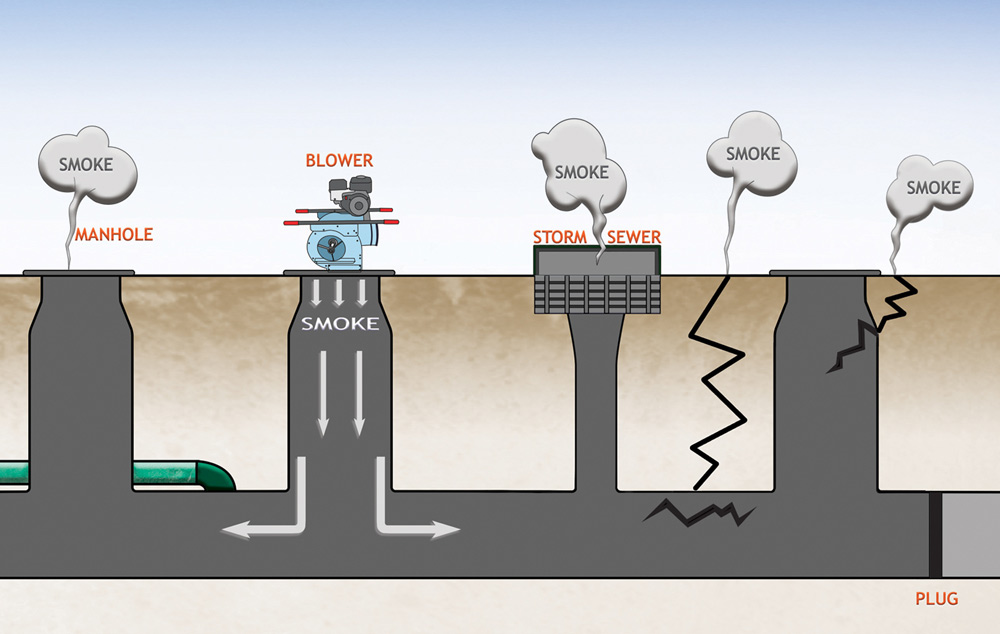

Smoke testing is a relatively simple process which consists of blowing smoke mixed with larger volumes of air into the sanitary sewer line, usually induced through the manhole. The smoke travels the path of least resistance and quickly shows up at sites that allow surface water inflow. Smoke will identify, broken manholes, illegal connections (including roof drains, sump pumps, yard drains and more), uncapped lines, and will even show cracked mains and laterals providing there is a passageway for the smoke to travel to the surface. Although video inspection is certainly an important component of I&I surveys, research has shown that approximately 65% of all extraneous stormwater inflow enters the system from somewhere other than the main line. Smoke testing is an excellent method of inspecting both the mainlines, laterals and more. Smoke travels throughout the system, identifying problems in ALL connected lines even sections of line that were not known to exist, or thought to be independent or unconnected.

Smoke testing is a relatively simple process which consists of blowing smoke mixed with larger volumes of air into the sanitary sewer line, usually induced through the manhole. The smoke travels the path of least resistance and quickly shows up at sites that allow surface water inflow. Smoke will identify, broken manholes, illegal connections (including roof drains, sump pumps, yard drains and more), uncapped lines, and will even show cracked mains and laterals providing there is a passageway for the smoke to travel to the surface. Although video inspection is certainly an important component of I&I surveys, research has shown that approximately 65% of all extraneous stormwater inflow enters the system from somewhere other than the main line. Smoke testing is an excellent method of inspecting both the mainlines, laterals and more. Smoke travels throughout the system, identifying problems in ALL connected lines even sections of line that were not known to exist, or thought to be independent or unconnected.

Sewer Smoke Blowers

Most engineering specifications for smoke testing identify the use of a blower able to provide 1750 cfm (cubic feet of air per minute), however in today’s world it seems to be the mindset that bigger is better. New smoke blowers on the market can deliver well over 4000 cfm, but is this really needed? Once the manhole area is filled, the smoke only needs to travel sections of generally 8 or 10-inch pipe. Moving the air very quickly is useless if the blower does not have the static pressure to push that air/smoke through the lines. If you’ve used high CFM blowers and found that smoke frequently backs up to the surface, this may be your problem.

There are two types of blowers available for smoke testing sewers: squirrel cage and direct drive propeller. In general, squirrel cage blowers are usually larger in size, but can provide more static pressure in relation to CFM. The output of the squirrel cage type is usually adjustable by alternating pulleys and belts to meet the demands of the job. Propeller style blowers are usually more compact and generally offer at least 4000 CFM. Other than reducing the engine throttle, the output is not adjustable since the fan blade is attached directly to the engine shaft.

Smoke Types

There are two types of smoke currently offered for smoke testing sewers, classic smoke candles and smoke fluids.

![]() Smoke candles were first used for testing sewers when the process began its popularity back in 1961. They are used by simply placing a smoke candle on the fresh air intake side of the blower. Once ignited, the exiting smoke is drawn in with the fresh air and blown down into the manhole and throughout the system. Smoke candles are available in various sizes that can be used singularly or in combination to meet any need. This type of smoke is formed by a chemical reaction, creating a smoke which contains a high content of atmospheric moisture. It is very visible even at low concentrations, and extremely effective at finding leaks.

Smoke candles were first used for testing sewers when the process began its popularity back in 1961. They are used by simply placing a smoke candle on the fresh air intake side of the blower. Once ignited, the exiting smoke is drawn in with the fresh air and blown down into the manhole and throughout the system. Smoke candles are available in various sizes that can be used singularly or in combination to meet any need. This type of smoke is formed by a chemical reaction, creating a smoke which contains a high content of atmospheric moisture. It is very visible even at low concentrations, and extremely effective at finding leaks.

Another available source of smoke is a smoke fluid system. Although they have just recently been more aggressively marketed, smoke fluids became available for sewer testing shortly after smoke candles, some 30 years ago. They can certainly be used effectively, but it is important to understand how they work. This system involves injecting a smoke fluid (usually a petroleum based product) into the hot exhaust stream of the engine where it is heated within the muffler (or heating chamber) and exhausted into the fresh air intake side of the blower. One gallon of smoke fluid is generally less expensive than one dozen smoke candles, however smoke fluids do not consistently provide the same quality of smoke. When using smoke fluid, it is important to understand that as fluid is injected into the heating chamber (or muffler) it immediately begins to cool the unit. The heating chamber will eventually reach a point where it is not hot enough to completely convert all the fluid to smoke, creating thin/wet smoke. This can happen quickly depending on the rate of fluid flow. If the smoke has become thin it can be especially difficult to see at greater distances. Blocking off sections of line is usually a good idea with any type of smoke, but becomes almost a necessity when using smoke fluid.

Smoke Testing Safety

Maybe one of the more talked about, yet least understood aspects of smoke testing is the use and safety of these products. As manufacturers have become more competitive, some marketing programs and advertisements have implied danger in the use of competitive types of smoke products. Laboratory reports, scientific studies, and even Material Safety Data Sheets can be quite confusing to most of us, who are not trained nor qualified to make scientific judgements on this data. Having this information delivered to us in the form of advertising can be dangerous, as most of us tend to believe what we read. Even the author of a recent trade article stated… “Do not use smoke bombs, as they give off a toxic gas”. Although the author quotes no scientific literature to support this statement, competitive propaganda has made such implications. It is interesting to note that the same exact statement could be made for smoke fluids. Smoke from fluid is created in the exhaust system of the engine, which contains carbon monoxide. Is carbon monoxide not a toxic gas?

When considering the safety of smoke testing it is important to use common sense. All smokes, candles and fluids can be used safely and effectively when certain guidelines are followed. Remember, breathing any type of foreign substance (including smoke of course) can cause irritation of breathing passages. The degree of irritation depends on the level of exposure as well as an individual's tolerance to that foreign substance. For example, someone in poor health or with respiratory ailments such as asthma or emphysema would be less likely to tolerate exposure to breathing a foreign substance, and should avoid exposure to any type of smoke, even though the amount of smoke present at any single leak would be a small percentage of the total smoke in the system.

When planning to smoke test, it is important to provide information such as this in a public notice program. Ads in local papers, door hangers, mailers, as well as door to door inquiries are recommended. It is helpful to educate the public as to why the test is being performed and the benefits to the community. In addition, it should instruct residents on what to do and who to call if smoke should enter their homes. It is also important to notify local police and fire departments daily, as to where and when smoke testing will be taking place.

Smoke testing has continued to be a low cost and effective technique for successful I&I studies. Although personal preference usually plays a large part in determining what type of smoke product is specified for a job, either type can work well when used properly.