Successful Leak Detection Using Ultrasonics

Escaping the frustrations of leak detection means recognizing the advantages and disadvantages of all the available techniques.

Over the past few years we have had conversations with hundreds of air conditioning and refrigeration contractors about leak detection. Of these unique individuals, one thing that remains constant are ill feelings toward leak detection.

So why are so many contractors frustrated with their leak detectors?

Is it that most of the equipment on the market is poorly made, and truly does not work?... It is true that some detectors are made better than others, but for the most part the leak detectors currently on the market will do the job as specified.

Are expectations of leak detectors too high?... This may be true. When you look at some manufacturer’s brochures and ads, they all lead you to believe that they will eliminate any and all frustration in finding leaks. One fluorescent dye/lamp manufacture even states in their ads “Find Every Leak”. Of the people we spoke to, no one knows of a detector that will find every leak, every time, in every situation.

Know the limitations of the equipment you use . . . Most service people are familiar with the limitations of the detectors they use, but for some reason choose to ignore them when judging the worth of the leak detector. For example, a contractor at a trade show mentioned to me that he had been unsuccessful in using the injected dye method, then later found the leak with an ultrasonic leak detector. This does not mean that the dye system did not work. In actuality, the dye did show up, however it was in an area that was not easily visible, or accessible with his lamp.

Many have formed strong opinions about what they like and dislike about certain techniques. Even those who seem relatively pleased with their leak detection equipment will readily agree that it doesn’t work ALL the time. The newest type of detector on the market is ultrasonics. Will ultrasonics find every leak? Of course not! They will however find leaks under conditions that severely hinder the performance of other methods. When deciding on a leak detector to use on a job it is very important to (#1) - Know your options, and (#2) - Know the advantages, and the limitations of these options.

Leak Detection Options

1. Sniffer type (Electronic or Halide Torch). Detect the presence of refrigerant gas in the atmosphere.

2. Visual types (Bubble solutions, or Dyes). Make the leaking area visible.

3. Listening types (Ultrasonic). Make the sound of the leak audible.

Sniffer Types

When using these type of leak detectors remember you are “sniffing” for a trace of the refrigerant gas which has leaked out. These types of detectors are incredibly sensitive to minute traces of gas (which can be measured in parts per million or ounces per year). The “sniffer” would most likely be your first choice when looking for a leak which is only loosing a few ounces over a long period of time. When using a “sniffer” the refrigerant gas must pass through the sensor of the detector in order for it to alarm. This can be difficult at times under certain conditions. Wind can be detrimental to your leak detection efforts, making it hard to capture the gas as it is blowing around. A sniffer type may also alarm from residual oils, containing refrigerant. When wind and/or contaminants make sniffers difficult to use, it’s time to try another method.

When using these type of leak detectors remember you are “sniffing” for a trace of the refrigerant gas which has leaked out. These types of detectors are incredibly sensitive to minute traces of gas (which can be measured in parts per million or ounces per year). The “sniffer” would most likely be your first choice when looking for a leak which is only loosing a few ounces over a long period of time. When using a “sniffer” the refrigerant gas must pass through the sensor of the detector in order for it to alarm. This can be difficult at times under certain conditions. Wind can be detrimental to your leak detection efforts, making it hard to capture the gas as it is blowing around. A sniffer type may also alarm from residual oils, containing refrigerant. When wind and/or contaminants make sniffers difficult to use, it’s time to try another method.

Visual Types

Bubble solutions, and ultraviolet dyes are two visual types of leak detectors. Bubbles are very inexpensive, and easy to use. They are also sensitive enough to indicate most of the leaks you will encounter. Bubbles are a great way to check a fitting or area where a leak is likely, however they

can become time consuming when every inch of the system would have to be checked. Fluorescent dyes are injected into the system, and illuminate when an ultraviolet lamp is used. Although it is more time consuming, this method is also capable of finding small leaks. Like bubble solutions, however, the leak must be accessible with the lamp, and the eye. If the leak is not within the users line of sight it will never be detected.

Listening Types

As the name implies ultrasonic leak detectors detect the ultrasonic sound of a leak. You are probably familiar with the hissing sound a large leak makes. Smaller leaks also emit sound, however the frequency is too high for our ears to detect it.

As the name implies ultrasonic leak detectors detect the ultrasonic sound of a leak. You are probably familiar with the hissing sound a large leak makes. Smaller leaks also emit sound, however the frequency is too high for our ears to detect it.

An ultrasonic leak detector lets the ultrasonic hissing sound be heard, and leads you to the source where the leak can be pinpointed.

Some leaks can be heard from several feet away, therefore access to the leak is not always necessary. As long as the leak is turbulent, there will be enough sound to be detected ultrasonically. High pressure is not necessary. Ultrasonics can detect pinhole leaks with as low as 1 psi. however, the more pressure behind the leak, the easier it will be to locate.

Ultrasonic leak detectors are very sensitive to sound, not refrigerant. A good ultrasonic leak detector can actually let you hear the blink of the human eye. A leak test can be done in an enclosed area which is saturated with refrigerant, and the only indication an ultrasonic will give you is the sound of the leak. Because the ultrasonic detector is focused on a specific band of sound... wind noise, voices, traffic, and most normal operational sounds will NOT be detected.

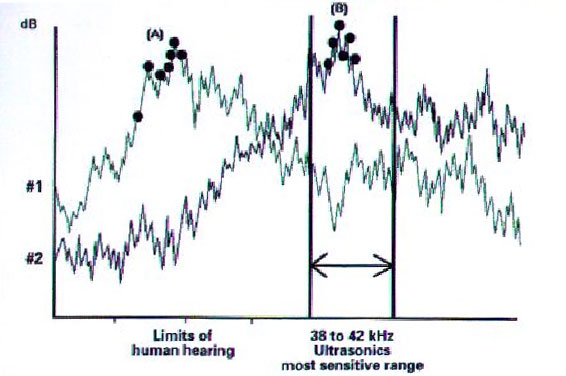

The graph to the left illustrates the sound spectrum you might find at a leak site. Line #1 is the backgound noise, and line #2 represents the sound (leak) we are trying to hear. Area “A” are the sounds most dominant to the human ear. However, the loudest point of the leak sound falls within the area of 38 to 42 kHz (area “B”) which is the range where an ultrasonic leak detector is most sensitive.

The graph to the left illustrates the sound spectrum you might find at a leak site. Line #1 is the backgound noise, and line #2 represents the sound (leak) we are trying to hear. Area “A” are the sounds most dominant to the human ear. However, the loudest point of the leak sound falls within the area of 38 to 42 kHz (area “B”) which is the range where an ultrasonic leak detector is most sensitive.

A good ultrasonic detector uses an electronic process called “heterodyning” to convert this high frequency leak sound to a lower range where the hissing of the leak can be heard through a set of headphones, and traced to its source. Any turbulent gas will generate ultrasound when it leaks, therefore it does not matter what refrigerant you are leak testing. Ultrasonic detectors will even detect air as it rushes into a system under vacuum.

Although ultrasonic detectors won’t “hear”most background noise, larger systems with a multitude of pressure regulating valves and high velocity flow, may produce the hissing type frequencies that fall into area “B” (where ultrasonic detectors are most sensitive). In this case it would be necessary to shut the system down, or use one of the other methods.

It is important to consider more than just raw sensitivity when choosing a leak detector. For example, a highly sensitive “sniffer” type which was rated to find .25oz. of refrigerant per year was tested in a controlled laboratory setting. Not the windy and dirty rooftop where you might be trying to use it. Always consider the capabilities, and the limitations of the methods used. No one leak detector will find every leak, every time. It is often a combination of all the available methods which will insure the highest rate of success.

This article was provided by Superior Signal Company, Inc., Spotswood NJ. Superior Signal manufactures several models of ultrasonic detectors for a variety of industrial applications. For more information contact the company at 1-800-945-TEST(8378), or use their website; www.SuperiorSignal.com